Missing Control Joints in Slab

Overview

A community college identified significant cracking and curling issues on the elevated concrete topping slab within an academic building. Concerns regarding concrete integrity and compliance prompted the management to commission a detailed forensic evaluation. The objective was to identify the causes of deterioration, assess compliance with design specifications, and recommend suitable remediation strategies.

Scope of Work

A comprehensive evaluation was performed involving visual inspections, and laboratory testings such as strength tests (ASTM C42) and petrographic analysis (ASTM C856). The investigation specifically targeted concrete quality, slab curling, cracking patterns, and reinforcement placement. Field evaluations documented crack locations, slab edge curling magnitudes, the presence and impact of radiant tubing, and the distribution and thickness of the sound control floor underlayment.

Key testing methodologies included:

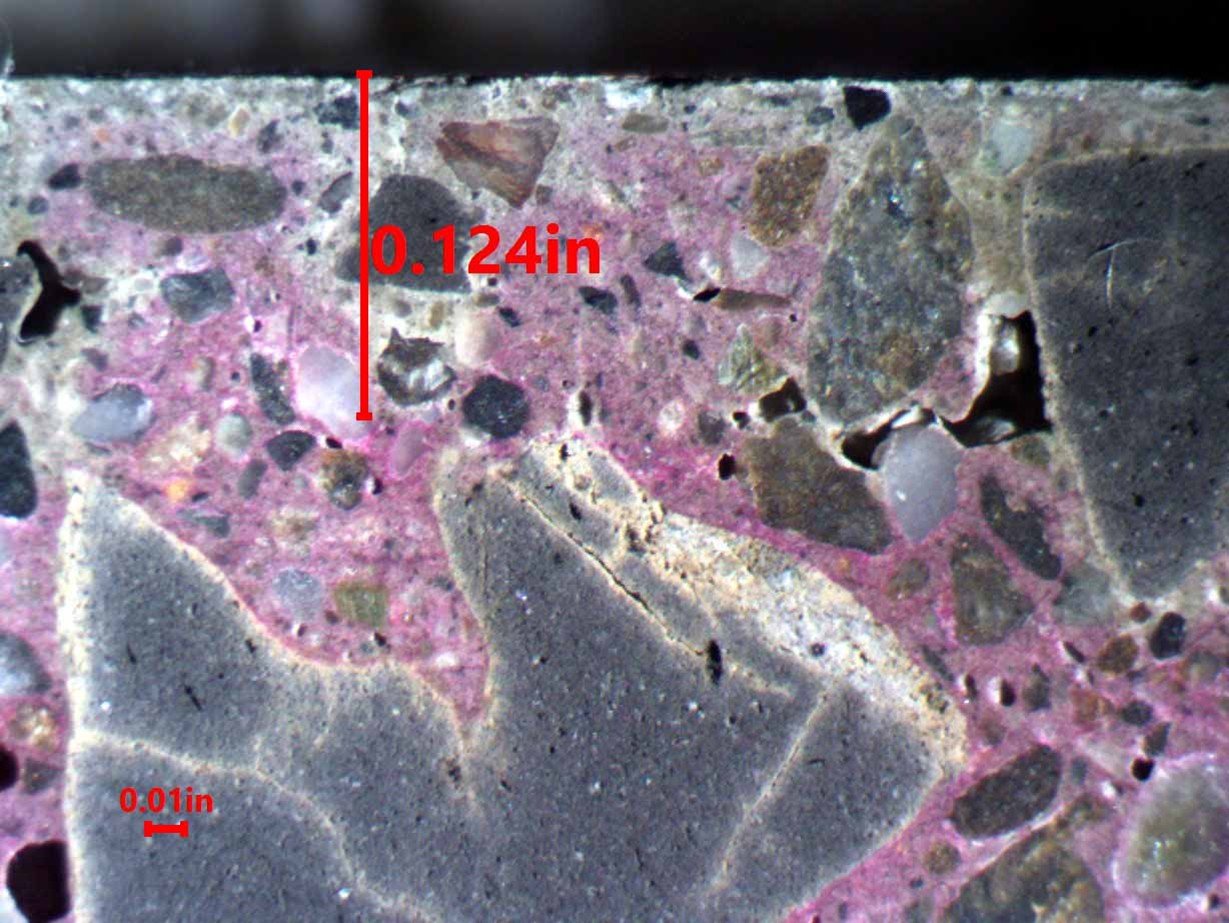

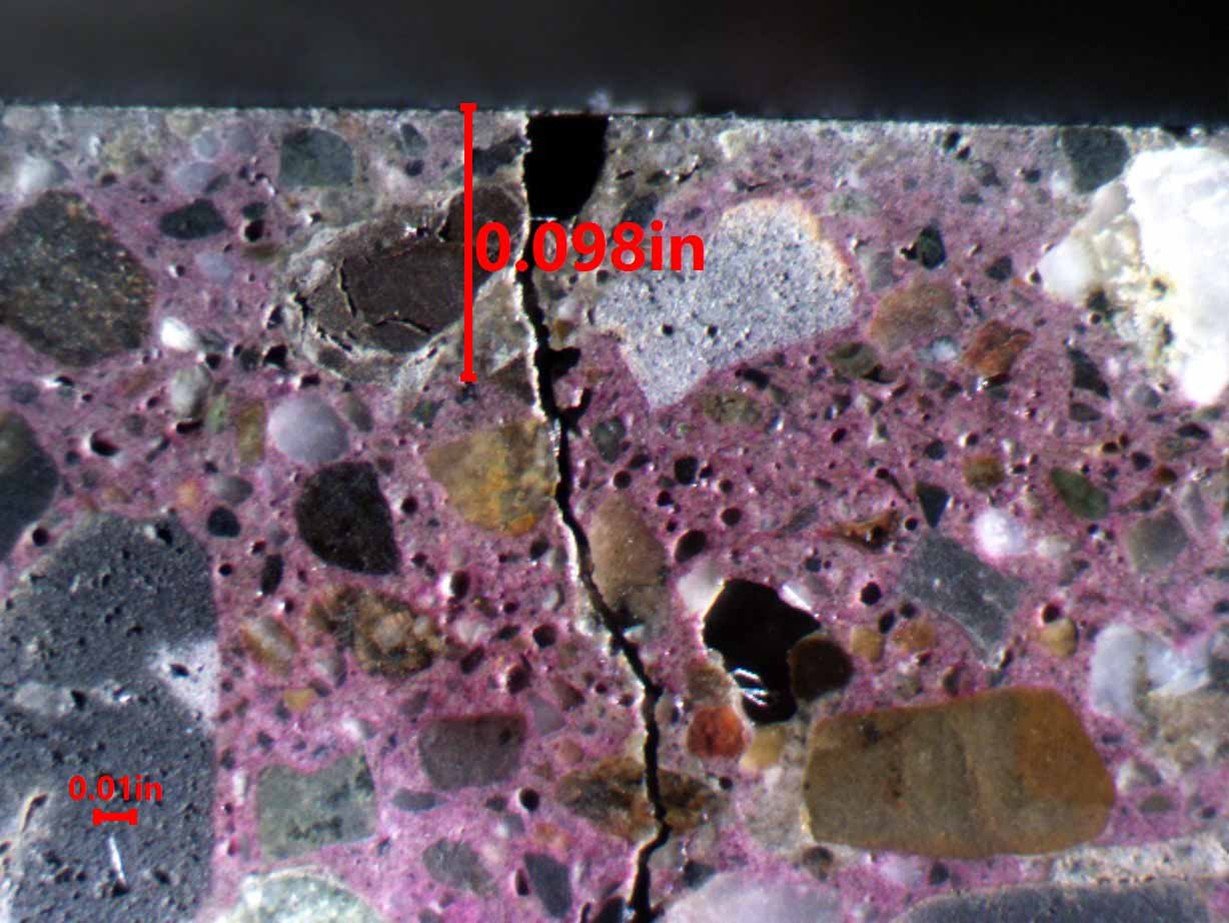

Petrographic Examination (ASTM C856):

Microscopic analysis of concrete cores to determine aggregate composition, cement paste quality, carbonation depth, and air void structure.

Examination of microcracking and paste-to-aggregate bonding.

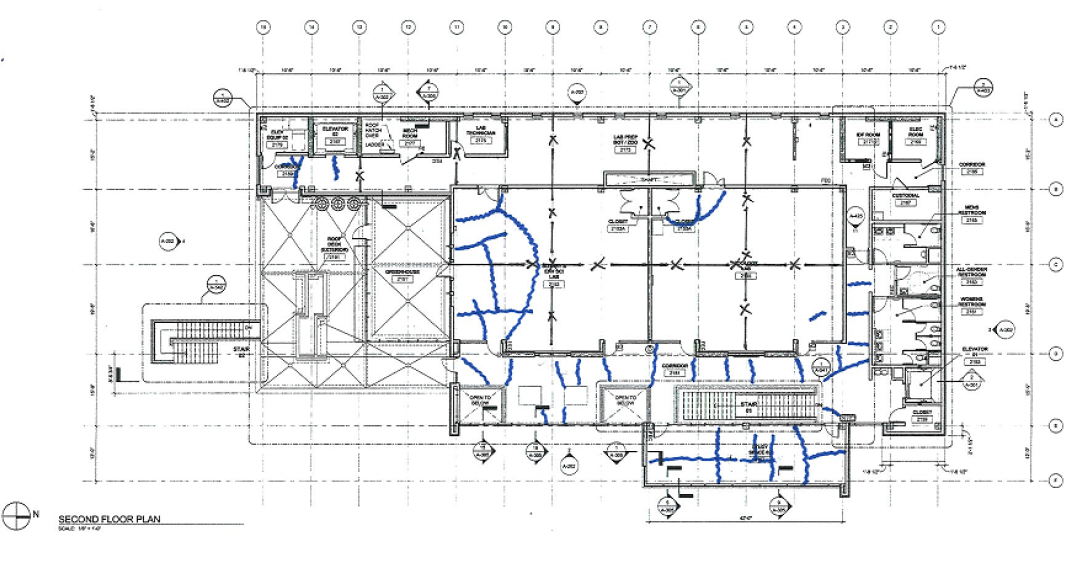

Detailed crack mapping to document crack patterns and slab edge curling.

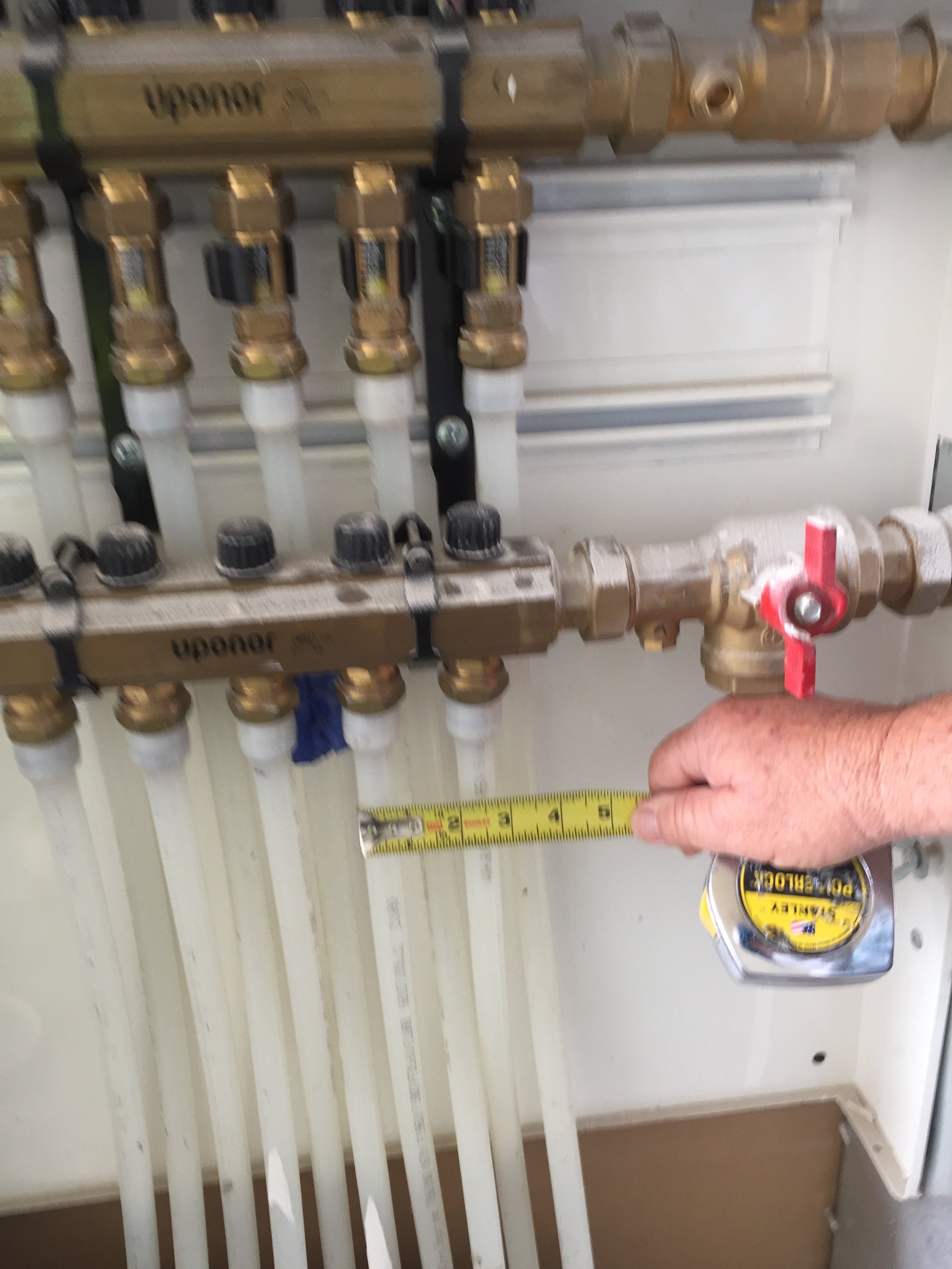

Examination of slab reinforcement, radiant heating tubing placement, and presence or absence of control joints.

Concrete core compression testing (ASTM C42); some initial cores contained fiber reinforcement.

Measurement of sound control floor underlayment thickness to verify compliance with specified requirements.

Key Findings

1. Concrete Composition and Quality:

Concrete Composition and Quality:

Lightweight concrete aggregates were well-distributed and adequately consolidated.

Compressive strength significantly exceeded the specified strength of 5,000 psi.

Cracking and Curling Issues:

Extensive slab cracking was primarily due to the lack of adequate control joints.

Curling up to ⅝-inch was primarily observed at slab corners, driven by drying shrinkage, thinner-than-specified topping slab thickness due to thicker sound control underlayment, and absence of control joints.

Construction Deficiencies:

The absence of control joints notably contributed to excessive cracking, particularly in areas with radiant heating tubing embedded in the slab.

Sound control underlayment measured between 17-18 mm, thicker than specified, causing reduced slab thickness and increased curling.

Solutions and Recommendations

Corrective Measures:

Repair core holes by reinstalling acoustic underlayment plugs and filling with high-strength non-shrink grout.

Fill slab cracks using appropriate crack filler.

Grind curled slab edges to comply with ADA's maximum ¼-inch vertical offset requirement.

Level slab edges with epoxy or cementitious leveling materials if grinding is insufficient.

Curl Mitigation:

Inject structural polyurethane foam beneath the curled slab edges to improve support.

Outcome

The detailed petrographic and structural evaluation clearly identified the causes of slab . Implementation of targeted recommendations effectively mitigated the slab's structural deficiencies, addressing compliance concerns and significantly enhancing slab performance and durability.